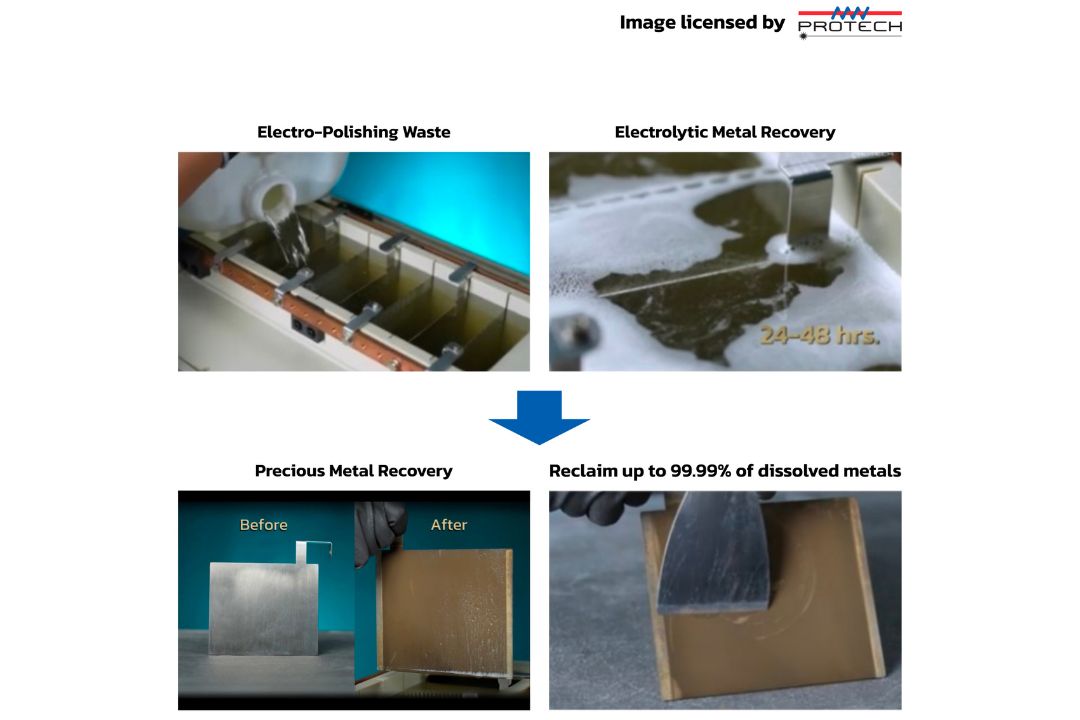

Discover how jewelry manufacturers can recover gold, silver, and rhodium from electro-polishing and plating waste using electrolytic metal recovery systems.

Recovering Precious Metals from Electro Polishing Waste: Turning Loss into Value

In jewelry manufacturing, precious metal counts. During electro polishing or plating, the waste liquids can hold significant amounts of valuable metals such as gold, silver, rhodium, etc. Often unknowingly discarded as waste.

Recovering Precious Metal in Liquids

When electro polishing solutions become saturated with dissolved metals or plating baths reach end of life time, they must be replaced. Common practice is to send these liquids to third-party waste treatment and refining.

From Waste to Asset: The Electrolytic Metal Recovery Process.

Electrolytic metal recovery systems provide a sustainable and cost-effective way to reclaim precious metals from plating and electro polishing baths. The process uses a controlled electrical current to attract and deposit dissolved metals onto a cathode, forming a metal layer that can be easily scraped off, turning it into metal powder. This recovered metal powder can be melted into metal blocks.

This technology not only minimizes environmental impact but also generates direct financial return transforming waste into a valuable resource.

Real Example: Rhodium Recovery from Polishing Solution

In one test using an electrolytic recovery system, a 5-liter sample of depleted Rhodium plating solution was processed for 36 hours in constant Voltage (CV) mode. The system successfully recovered 1.5 grams of Rhodium, valued at approximately 12,000 THB, with only 96 THB in electrical operating cost.

This example clearly demonstrates how much hidden value remains in spent process solutions especially when dealing with high-value metals like Rhodium. This provides a very high Return of Investment (ROI) value.

Why Jewelry Manufacturers Should Consider Metal Recovery?

Implementing a precious metal recovery system in the electro polishing or plating process allows jewelry manufacturers to:

- Recover Gold, Silver, Rhodium, and other metals directly

- Reduce waste disposal costs and hazardous waste volume

- Meet environmental compliance standards with lower discharge limits

- Improve sustainability through circular production practices

- Gain measurable ROI from materials already in use

This approach supports both profitability and environmental responsibility in sustainable jewelry manufacturing.

Solution Spotlight: ProClaim Precious Metal Recovery System

For jewelry manufacturers seeking an efficient, closed-loop solution, the ProClaim Precious Metal Recovery System offers advanced electrolytic metal recovery designed to reclaim up to 99.99% of dissolved metals from electro-polishing and plating solutions.

Its closed chamber ensures operator safety with high-purity recovery with minimal maintenance.

By integrating ProClaim into your production line, you can turn waste liabilities into valuable assets achieving cleaner processes and direct cost savings.

Interested to learn more about metal recovery for your polishing process? Contact Protech Transfer to discover how the ProClaim System can be integrated into your workflow.

Explore ProClaim Precious Metal Recovery System

(https://protech-transfer.com/protech/protech-proclaim/)

BEST MACHINERY – BEST SERVICE

Sales Hotline: +66 8 6332 9347

LINE ID Sales: @pttsales

24/7 Service Hotline: +66 8 9227 9154

LINE ID Service Support: @pttsupport

See all machines