INDUTHERM

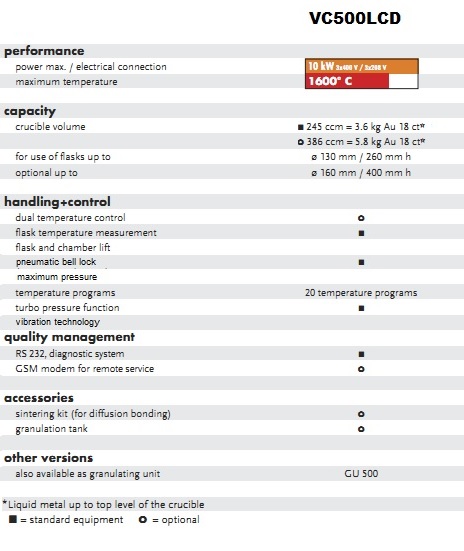

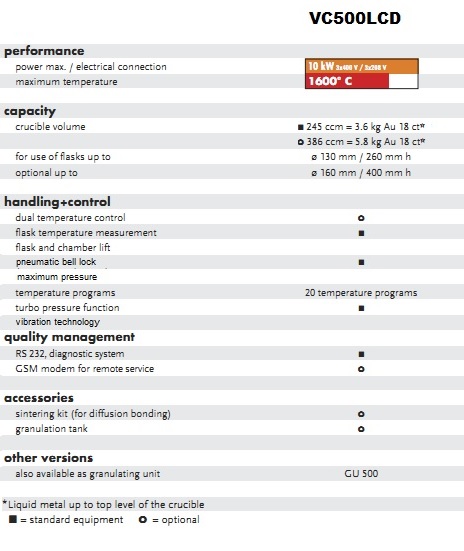

All Indutherm VC machines have separate lock systems for the melting chamber and the flask chamber. This allows time to be saved by “overlapping” casting. While the flask remains in the flask chamber for several minutes after the casting, the next charge of metal can be filled in and heated up already.

The optional equipment with VC or CC machines with a separate granulation tank is a suitable solution for occasional graining.

Advantages are:

> easy installation of the tank

> fast changing between casting processes and granulating

> ergonomically and perfectly balanced design for safe and easy handling

> optimized streaming behavior of the cooling water

> reliable seperation of water and granules