Indutherm

New & Highly Cost-Effective

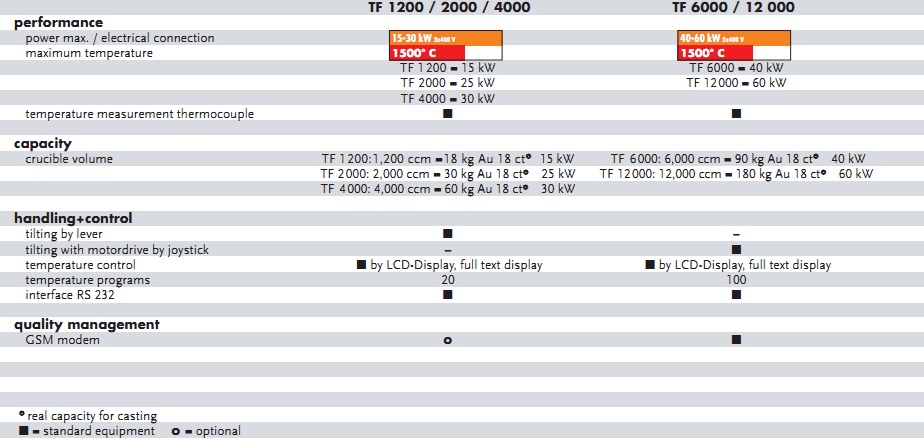

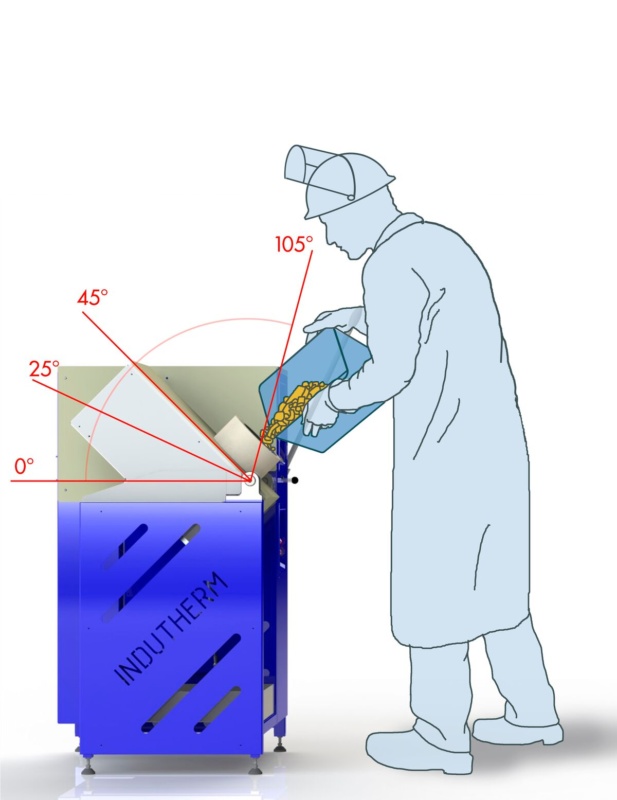

The new “small” TFs (TF1200-TF4000) have been developed with the focus on least possible energy consumption and safe/ergonomic handling. Offering the same maximum outputs like before, the effective power consumption now has dropped significantly – on a level where competitor machines cannot go with.

The Giants Among Tilting Furnaces

The large crucible volumes between 6000 – 12000 ccm (TF6000 & TF12000) give these machines enormous capacity. Because of the potentially large weight, the inductor/crucible unit uses a motor drive with a stable shaft. The use of a joystick enables the tilting process in a controlled and sensitive way.