Desktop Size or Stand-Alone

It really does not matter … with its unbeatable price-performance ratio and the lowest running cost in the market, DigitalWax® J Series are the perfect choice for fast production of high quality models. Main features are:

> BluEdge® laser source

> High speed and accuracy

> High surface quality

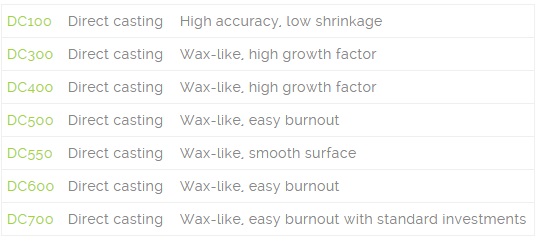

>Direct casting

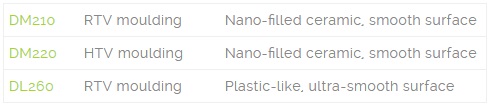

>Master models for rubber moulds

>Extra-long life UV laser

>No lamp replacement

>No calibration

>The lowest running cost