INDUTHERM

Melting Units MU Series

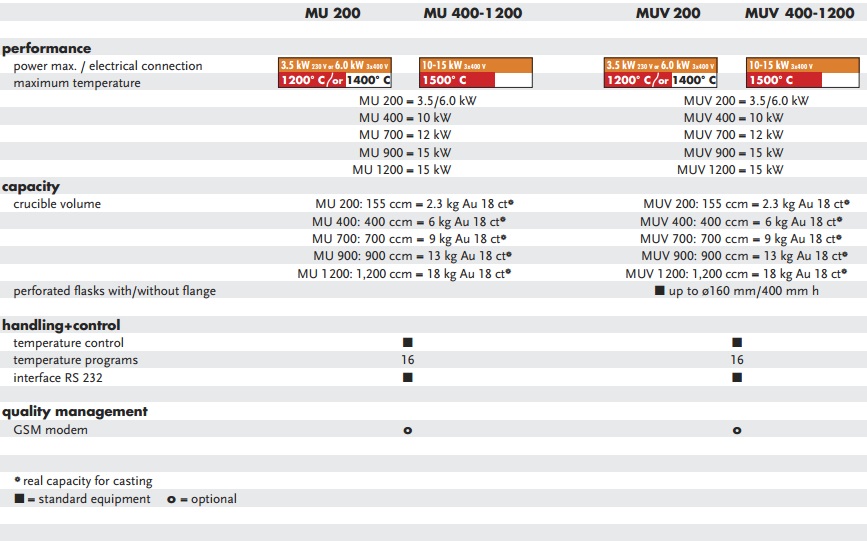

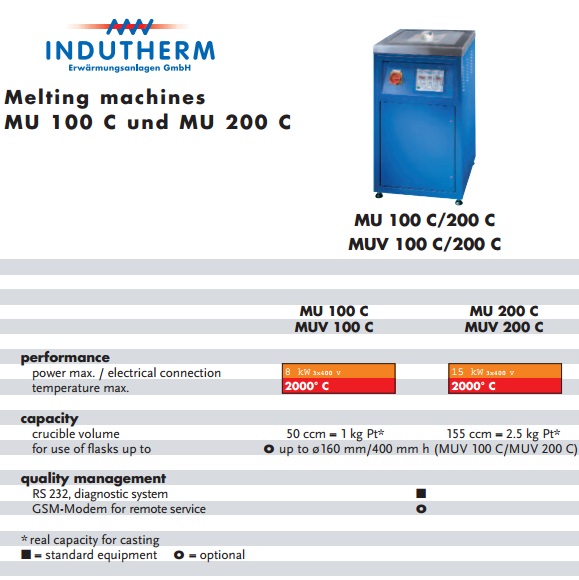

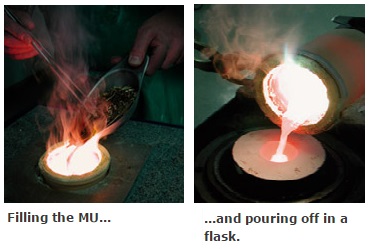

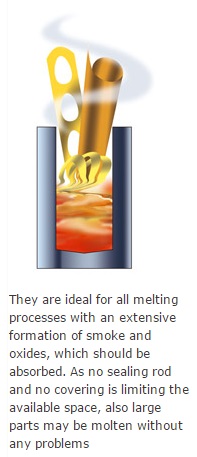

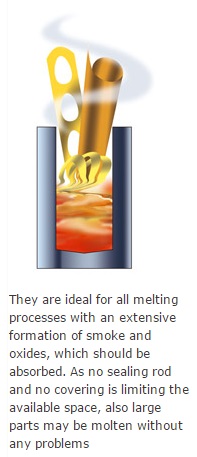

Flexible melting furnaces designed to melt gold and silver alloys and as well as aluminium, bronze, brass a.s.o. Due to the strong induction generator up to 15 kW and the low induction frequency the stirring effect of the metal is excellent.

The MU as vacuum casting machine

The V-versions include one or two additional extra large capacity vacuum chambers. The evacuation of the flask immediately after pouring improves the form filling, reduces porosity and avoids the oxidisation of the hot metal.