EF Flex Series - Otec Electrofinishing Equipment

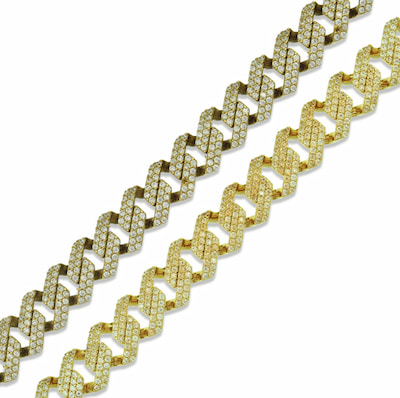

Processing of delicate and intricate pieces of jewellery with complex geometries requires particularly gentle smoothing and polishing. The EF-Flex reaches a new dimension of sparkling brilliance even on pieces of jewellery set with stones. Manual work is minimised. Perfect process reliability, processing even in the smallest of corners, and extremely short process times ensure cost-effectiveness and.

APPLICATION AREAS:

Bracelets, bangles, pendants, rings and necklaces in yellow, red and white gold, silver, brass and stainless steel.

HIGHLIGHTS:

- Processing in hard-to-reach areas and inner contours

- Intricate geometries are maintained and are smoothed and polished gently

- Excellent polish on gemstone settings without rounding

- Exceptionally shiny diamonds thanks to the polished setting

- No damage to diamonds, zirconia or gemstones

- Machine processing replaces up to 90% of all time-consuming pre-polishing and filing

FEATURES:

- Cyanide-free abrasives with no aggressive acids – no suction required

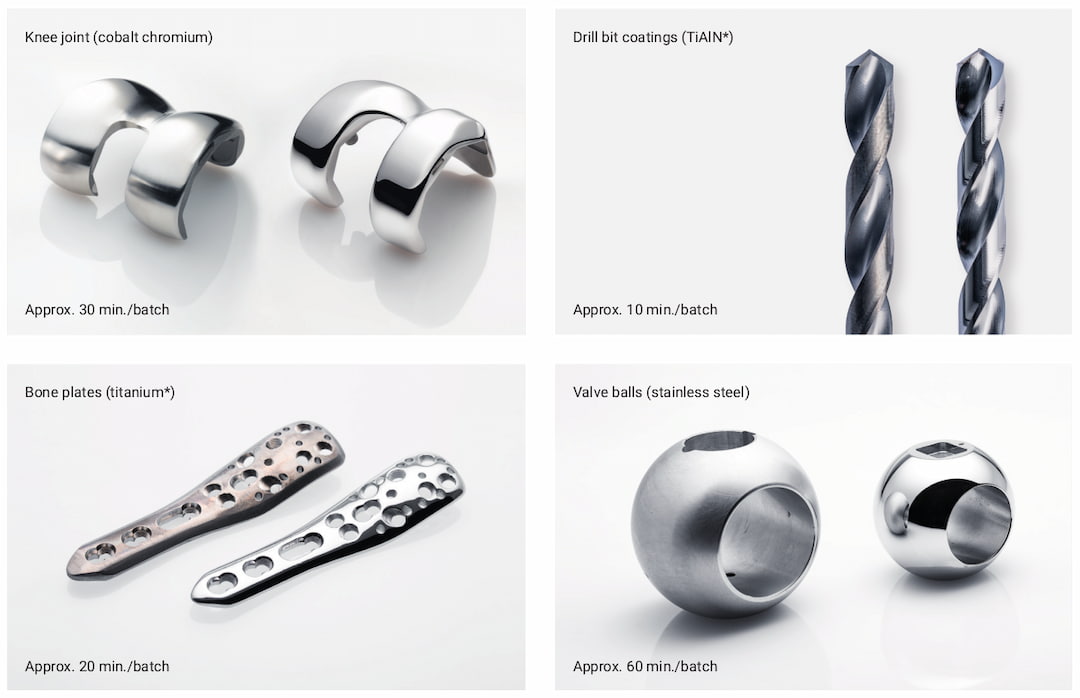

- Reproducible and fast results in a process time of just 10-20 minutes

- Easy recovery of abraded gold through filtration of the electrolyte and separation at the cathodes

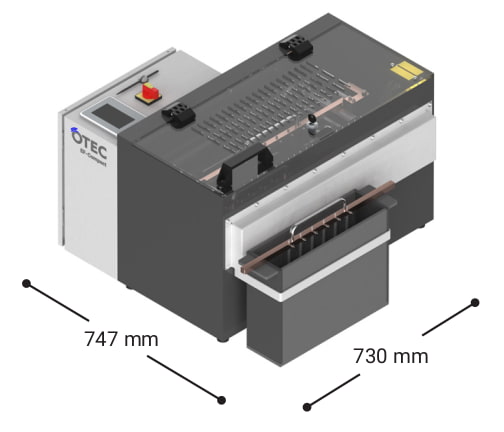

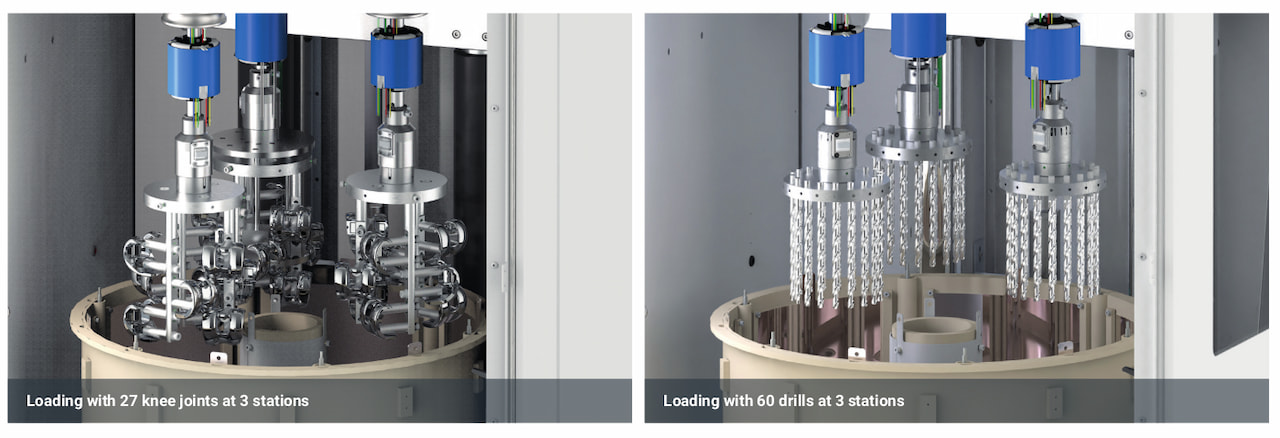

- Modular Electro Finishing Machine for up to 40 workpieces per process container

- Flexible design allows up to 3 process containers to be added as required

- Intuitive touch panel control and “recipe” database with workpiece-specific standard programs

- USB port for easy software updates

- Remote control, remote maintenance and OPC UA interface options